GERMANY/INTERNATIONAL

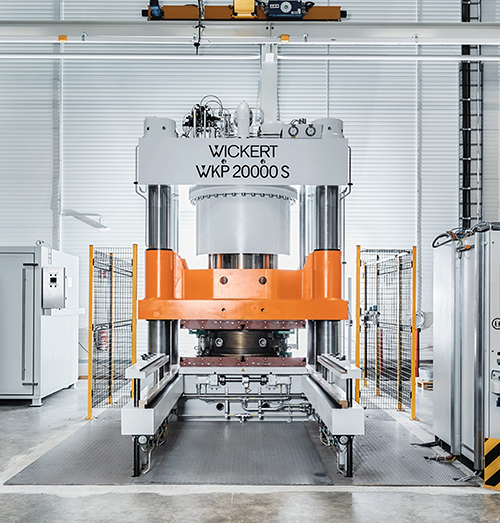

Maxi-Press is now producing membranes with its new, fully automatic elastomer press from Wickert Maschinenbau GmbH. The press, which was specially developed for Maxi-Press and has a clamping force of over 2,000 tonnes, is used specifically for the production of the world's only antibacterial extraction membranes, ‘Anti-Bact’, and has been in operation at the Eichenzell site near Fulda since the end of 2020. Maxi-Press, the global market leader for extraction membranes in laundries, invested around €1 million in the new production plant.

Maxi-Press relies on the highest quality and reliability when selecting the individual machine components. "The high quality and lasting durability of the individual parts made in Germany is absolutely essential when dealing with a clamping force of up to 20,000 kilo-Newtons," said Tim Zaiser, managing director of Maxi-Press Elastomertechnik GmbH. “The development time for the huge 80-tonne machine was around two years. After the two-month long installation in East Hessen, the WKP 20.000 S now works about 18 hours a day. This cutting-edge technology enables Maxi-Press to use newly developed production methods. For example, in addition to the documentation of all parts, constant control and visualisation of the temperature within the 18 heating circuits is guaranteed. Mixing and weighing according to the recipe, pressing, vulcanising and all other steps are carried out and documented fully automatically by the machine.”

The enormous closing force of the Wickert press enables the compression of new rubber compounds with a higher natural rubber content. This promotes the elasticity of the membranes. The continuous high temperatures of the 18 heating circuits increase the service life of the membranes during the laundry pressing process. Only the combination of high clamping force and optimal temperature distribution achieves the desired quality of the produced article. The further development of the existing rubber compounds and the additional functions of the new machine make future product development possible.

The German Hohenstein testing institute has confirmed the sterility of the Anti-Bact membrane with its seal of approval. The Anti-Bact membrane is a certified and protected product of Maxi-Press Elastomertechnik GmbH and prevents the transfer of germs to the laundry when pressed.