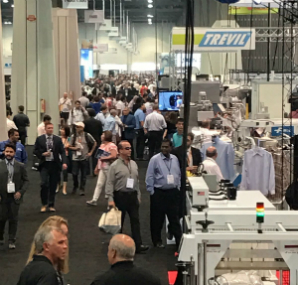

Clean Show 2017 – or using its official name World Educational Congress for Laundering and Drycleaning – delivered all it promised in its 40th year with the organiser claiming record footfall during the event. Turnout was up for both attendees and exhibitors over the four days of the show last month, according to figures from organiser Riddle & Associates. The total number of at the final count hit 12,563 people, a substantial increase on the 11,264 visitors at Clean 2017 in Atlanta.

All the big name manufacturers and suppliers were there and many new developments for the North American market made their debuts. Big news at Clean 2017 included the announcement from Lapauw International that the company has developed continuous tunnel washing systems, allowing the company to provide total laundry solutions. A new division of the group will be responsible for design and production of tunnel washers, presses, dryers, conveyors and all other supporting equipment.

The first Lapauw first continuous tunnel washing system is expected to be installed and operational by the end of 2017. Steven Renders, CEO of Lapauw International explains that the move was planned over many years. “We have brought a number of people on board over the past several months and years who have relevant experience in the field of tunnel washers, and they will help us to lead and build the new division,” he says.

The new Lapauw product range will include tunnel washers with capacities of 35, 50, 70 and 100kg, a 50-bar press, and both steam- and gas-heated dryers. Philippe D’heygere, president of Lapauw International adds: “The tunnel washer was clearly missing in our product range and we had to decline many requests from our customers for this kind of equipment.“ On its stand at the show, Lapauw USA showcased two new Lapauw ironers, a new small piece folder, the Mediwave barrier washer, and the HotSTREAM garment finishing tunnel. Lapauw promises demonstrations of its new tunnel washer system in Belgium later this year, and plans to present its full product range, including tunnel washer, at Expo Detergo in Milan next year.

Another piece of hot news released at the show was the announcement that HJ Weir is now the exclusive authorised distributor in the UK and Ireland for Milnor. “We are thrilled to be working with the Milnor family brand. There is a real synergy with business ethics and vision for the future. We already have had requests for Milnor products and we look forward to meeting many more laundries to showcase the full range,” says Ross Weir, managing director of the UK based company.

Milnor itself featured its new 8-module 76039 PBW tunnel system (with an MP1650 single-stage press and 6458TG pass-through dryer). In addition to the PulseFlow technology tunnel, Milnor launched its PurePulse water recovery treatment system. The 18-membrane PurePulse system combines high flux efficiency and superior filtration performance to help commercial and on-premise laundries achieve significant water and energy cost reductions.

Meanwhile, Lavatec Laundry Technology introduced its new ride-on shuttle, the LT50 110-pound continuous tunnel washer, and the osLaundry software system. Lavatec sold the majority of its booth equipment to several customers during the four-day event.

“We are thrilled with the results of this year’s Clean Show,” says Keith Ware, Lavatec vice president of sales. “We enjoyed many good conversations with customers and others about our new and existing equipment, including the TT-series Ecodry dryers. As expected, the ride-on shuttle was a hit with everyone. It was located along the main aisle and it stopped people in their tracks.”

Cintas has purchased the first model and also bought the Lavatex LX445, a 450-pound open pocket two-way tilting washer extractor and a Lavadry TT-756 G, a 450-pound pass-through single tilting gas fired dryer. Cintas plans to have the machines in operation at its Yonkers, New York facility later this year.

Jensen was preoccupied with ‘the elephant in the room’ on its stand which in this case was its new press with a press efficincy equivalent to “150 elephants” according to Gerda Jank and ,

For Kannegiesser E-tech, the merger of the two companies brought in the established Etech factory in North America makes the brand a one-stop shop for everything laundry including rail systems. A big bonus for USA customers is that rail systems no longer have to shipped out from Kannegiesser’s UK plant thereby slashing costs for customers.